SUSTAINABLE PLASTIC RECYCLING

Efficient

1 kilogram of plastic waste turns into 1 liter of new fuel

Profitable

Almost worthless waste becomes valuable energy

Scalable

Modules can easily be connected in parallel

Powerful

Energy for more than 200 people per system

Safe

Fully automated with worldwide support and remote monitoring

Sustainable

Solution for the global plastic waste problem

PROCESSES

1.000 KG

PLASTIC WASTE

PER DAY

NEEDS

1 kWh

PER KG

PLASTIC WASTE

1 KG

PLASTIC

TURNS INTO

1L FUEL

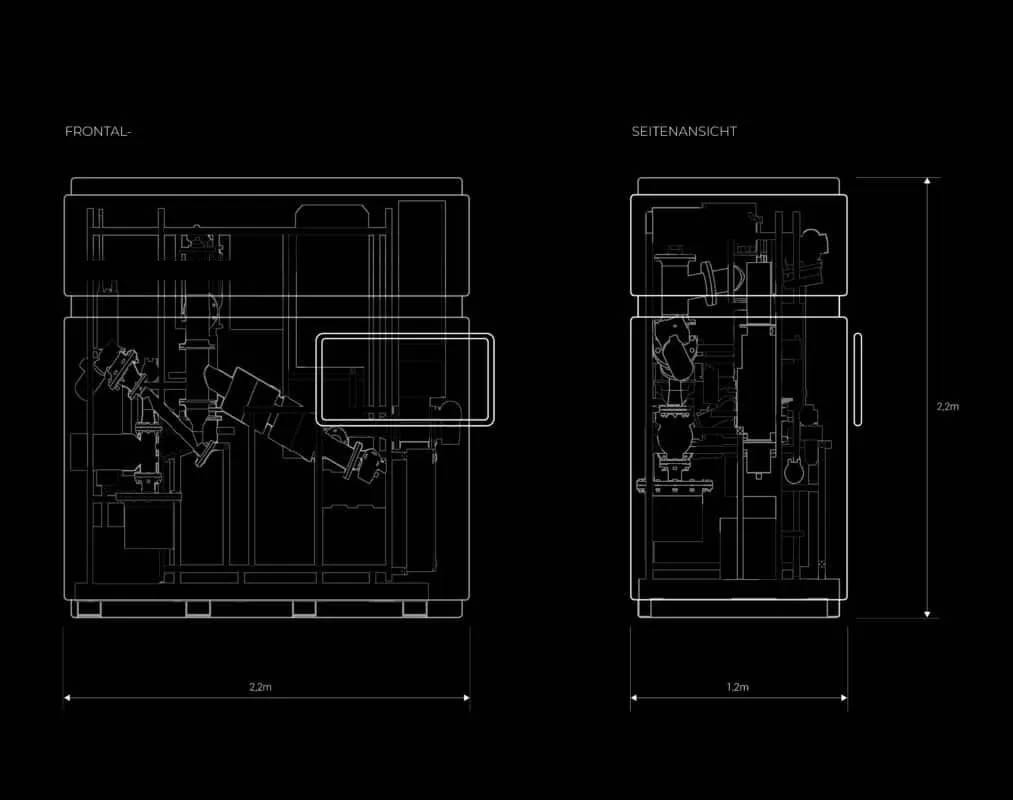

WASTX PLASTIC – DATA SHEET

19″ touch display

Compacting application system also for light

substrates

Continuous compact pyrolysis reactor with

multi-zone heating system

Condensation tanks with filtration

Siemens control system with

extensive sensor technology,

safety system

Water cooling + backup system

Automated ash removal

From 1.000 kg per day and module

Polyolefins: PE, PP, LDPE, HDPE

Up to 2% contamination according to

Black/Whitelist

Pyrolysis condensates (energy content approx.

10 kWh/l, up to 250 l/d)

HDPE

Containers, IBCs

Sheets, foils Injection

moulded parts of packaging, household goods

or technical articles

LDPE

Films such as cling films, Carrier bags

Agricultural films, milk carton

coatings Garbage bags and shrink films

PP

Interior fittings for passenger cars, dashboards and battery housings

Crash absorbers, child seats, bicycle helmets

Transformer housings, wire and cable sheaths Insulating

foils, pipes, cups, bottle closures

Interior parts for dishwashers, thermal transport

boxes Cooking resistant foils, reusable containers

packaging parts, drinking straws, adhesive foils

plastic banknotes such as the Australian dollar

PP fibers in home textiles, carpets, sports textiles, packaging materials,

hygiene products, medical products, floating ropes, geotextilesSUBTRATE TEST